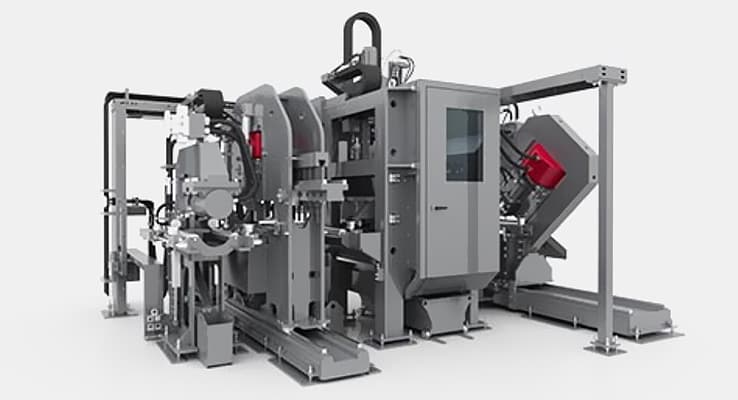

Welder Equipment

Are you looking for reliable machines that can be used in structural fabrication? We have the structural fabrication machinery you need to ensure that your beam and plate fabrications are as efficient as possible. These machines include plate processors. These machines also include beam drilling lines. Angle masters. Layout markers. Beam cambering.